ZHEJIANG JINGDUN TECHNOLOGY CO.,LTD.

Main technical parameters

| Parameter table | ||

| Maximum spin diameter | mm | Φ 400 |

| Maximum machining diameter and length | mm | Φ three hundred × 280mm |

| Bar operation capability | mm | Φ 45 |

| Spindle revolution | rpm | 35-5000 |

| Spindle end form | ASA | A2-5 |

| Spindle through hole | mm | Φ 56 |

| Stroke (x / z) | mm | 180/340 |

| Rapid feed rate | m/min | 30/30 |

| Number of tool positions | EA | 8(12) |

| Boring bar diameter | mm | Φ 25 |

| Tool position and body size | mm | 20 × 20 |

| Specification of x-direction and Z-direction screw rod | X:3210 Z:4010 | |

| X-direction and Z-direction track specifications | X:35 Z:35 | |

| Tailstock travel | EA | 170 |

| Taper hole of tailstock sleeve | mm | MT4 |

| Tailstock sleeve stroke | mm | 90 |

| Spindle motor (continuous / 30) | kw | 5.5/7.5 |

| Bidirectional positioning accuracy (machine tool accuracy) | mm | 0.008 |

| Bidirectional repeat positioning accuracy | mm | 0.003 |

| Lubrication pump | W/C | 20 |

| Cooling pump | kw | 0.45 |

| Power capacity | kVA | 11 |

| Chuck size | inch | 6 inches |

| Total mechanical weight | Kg | 2200 |

| Machine tool dimensions (L * w * h) | mm | 1650(1990)*1600*1650 |

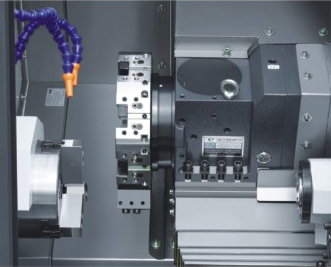

Main configuration

| Main configuration | ||

| Projects | Brand | Origin |

| Numerical control system | New generation 6ta-e | Taiwan |

| Bus servo driver | New generation original | Taiwan |

| 10. Z-axis absolute value servo motor | New generation original | Taiwan |

| Main servo motor (7.5kw-1000) | Alpha | Shenzhen |

| A2-6 spindle | NSK bearing | Japan |

| Track | THK | Japan |

| Ball screw (grade C3) | Yintai | Taiwan |

| Screw rod bearing | NSK/NTN | Japan |

| Main electrical components | Schneider | Germany |

| 852 hollow rotary cylinder | Bedford | Domestic |

| 8-inch hollow hydraulic three jaw chuck | Bedford | Domestic |

| 2.0kw Taiwan spline pump hydraulic station | Jingdun special | |

| Cooling water pump 450W | Nork | Taiwan investment |

| Automatic lubrication pump (gear pump) | Sheng Xiang | Taiwan investment |

| Inner guard | Central | Taiwan investment |

| Screw coupling | Hongwang | Taiwan |

| 100-8t servo turret (25 cubic meters) | Cheng Xin | Taiwan |

| Heat exchanger | Jingwo | Domestic |

| Hydraulic tailstock | Jingdun special | |

| Equipped with Siemens 808d system, x, Z axis motor and driver are Siemens original | ||

| Equipped with Mitsubishi e80a system, x-axis and z-axis motors and drivers are original made by Mitsubishi | ||

| Equipped with FANUC 0I TF system, x-axis and z-axis motors and drivers are original FANUC | ||

Local display